Collection:

Warehouse Lighting

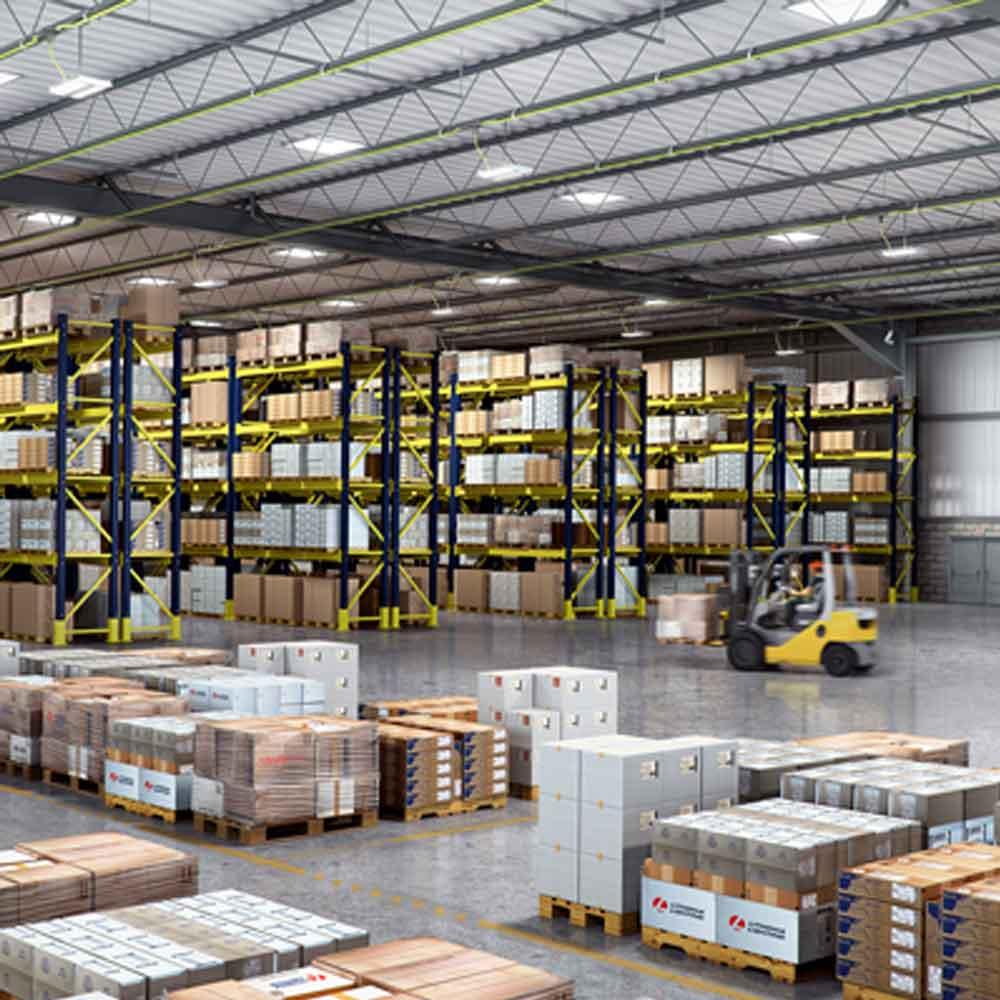

Warehouse lighting refers to the array of high-efficiency fixtures designed to safely and effectively illuminate large industrial spaces. Upgrading to modern LED solutions like high bays, strip lights, and vapor tight fixtures boosts productivity and drastically cuts energy consumption.

372 products

Filter

2ft Linear High Bay LED Light, 150 Watts 24000 Lumens, 5000K, 120/277V

Choose your option

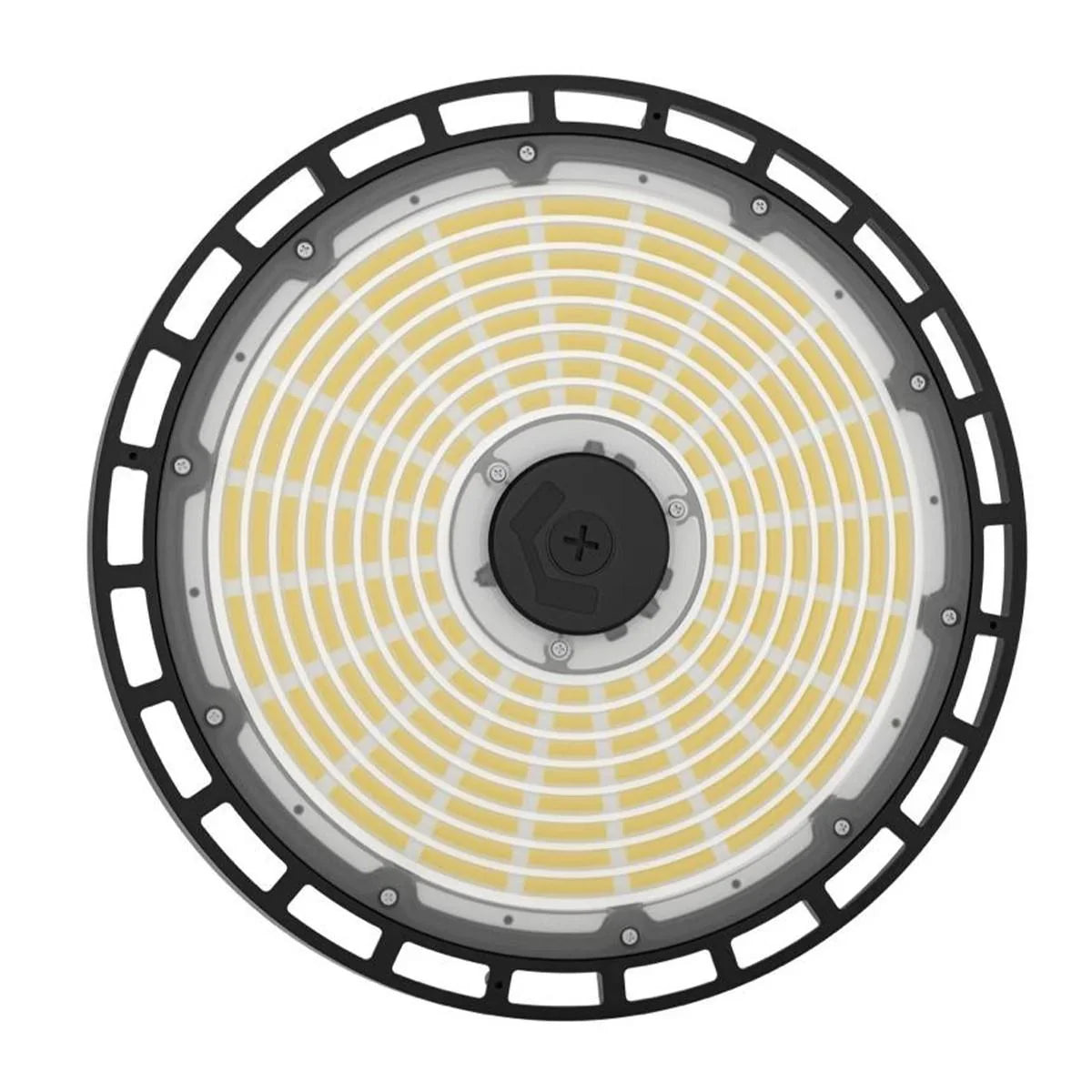

UFO LED Light, 240W, 38400 Lumens, 4000K/5000K, 120-277V

Choose your option

UFO High Bay Light, 150W, 24000 Lumens, 4000K/5000K, 120-277V, Black

Choose your option

UFO High Bay Light, 200W, 32000 Lumens, 4000K/5000K 120-277V, Black

Choose your option

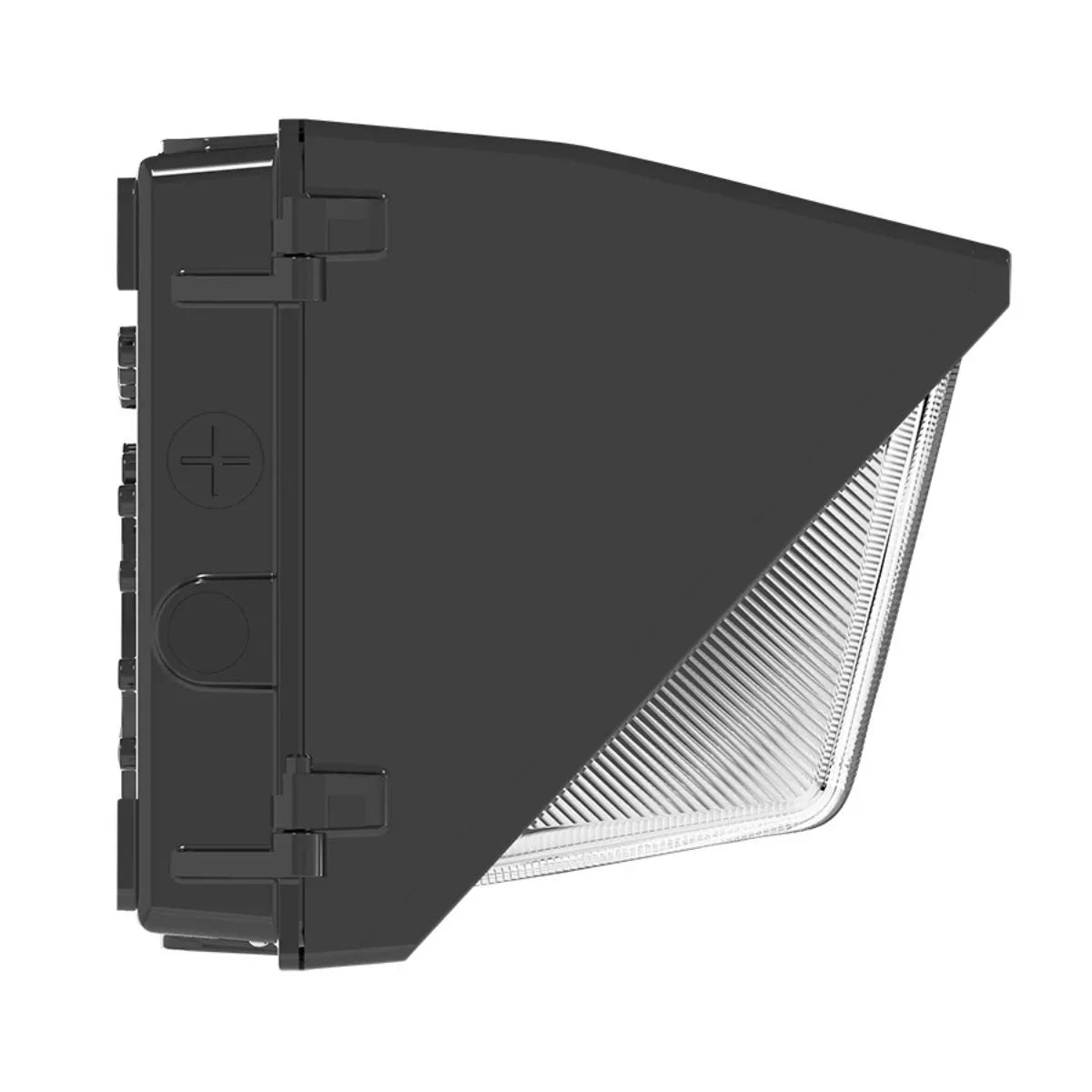

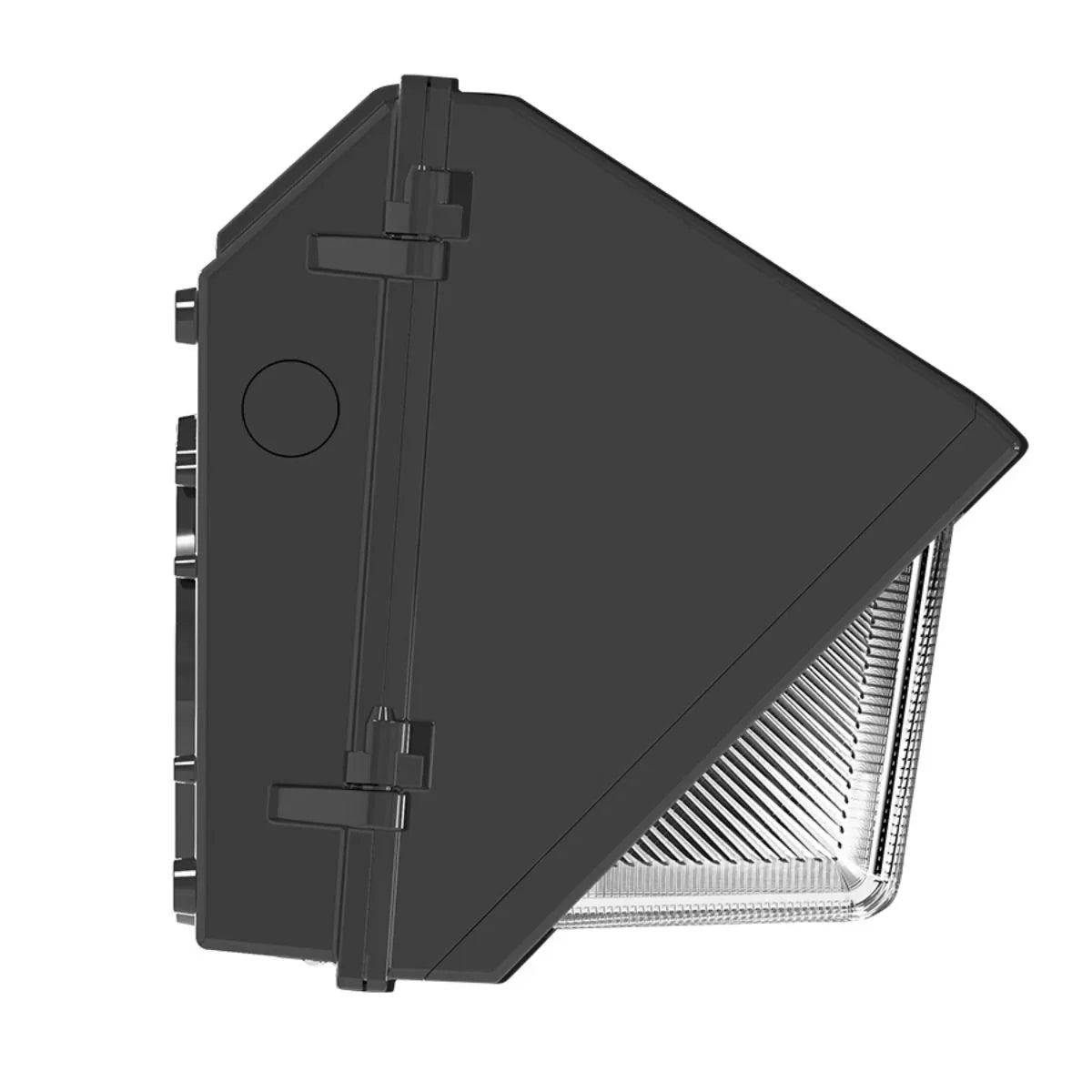

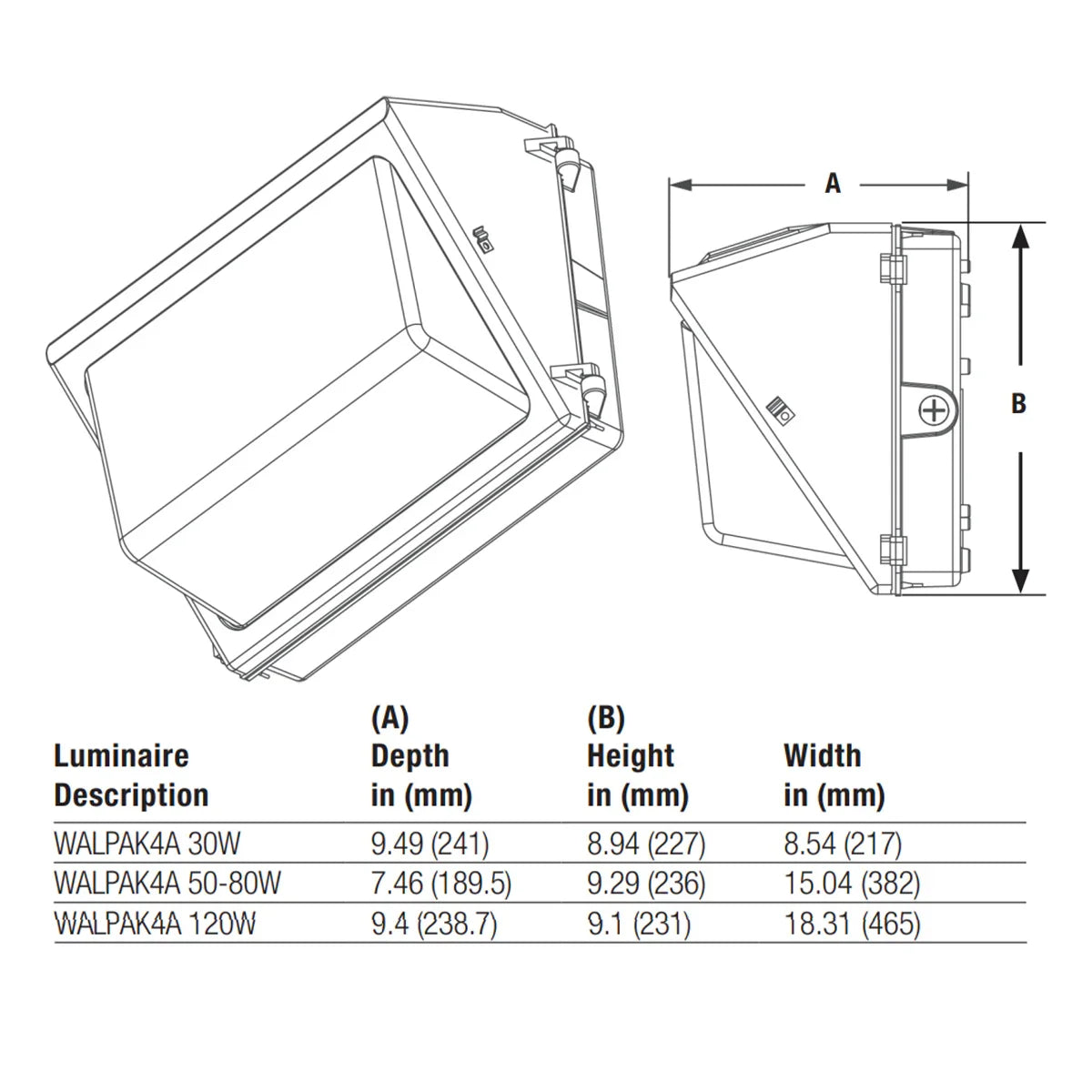

LED Wall Pack, 21000 Lumens, 150 Watts, 30K|40K|50K, On/Off Photocell, 120-277V

Choose your option

LED Mini Wall Pack, 16W, 1600 Lumens, 30K/35K/40K/50K/65K, 120V

Choose your option

LED Wall Pack, 100 Watts, 12000 Lumens, 30K/40K/50K, 120-277V

Choose your option

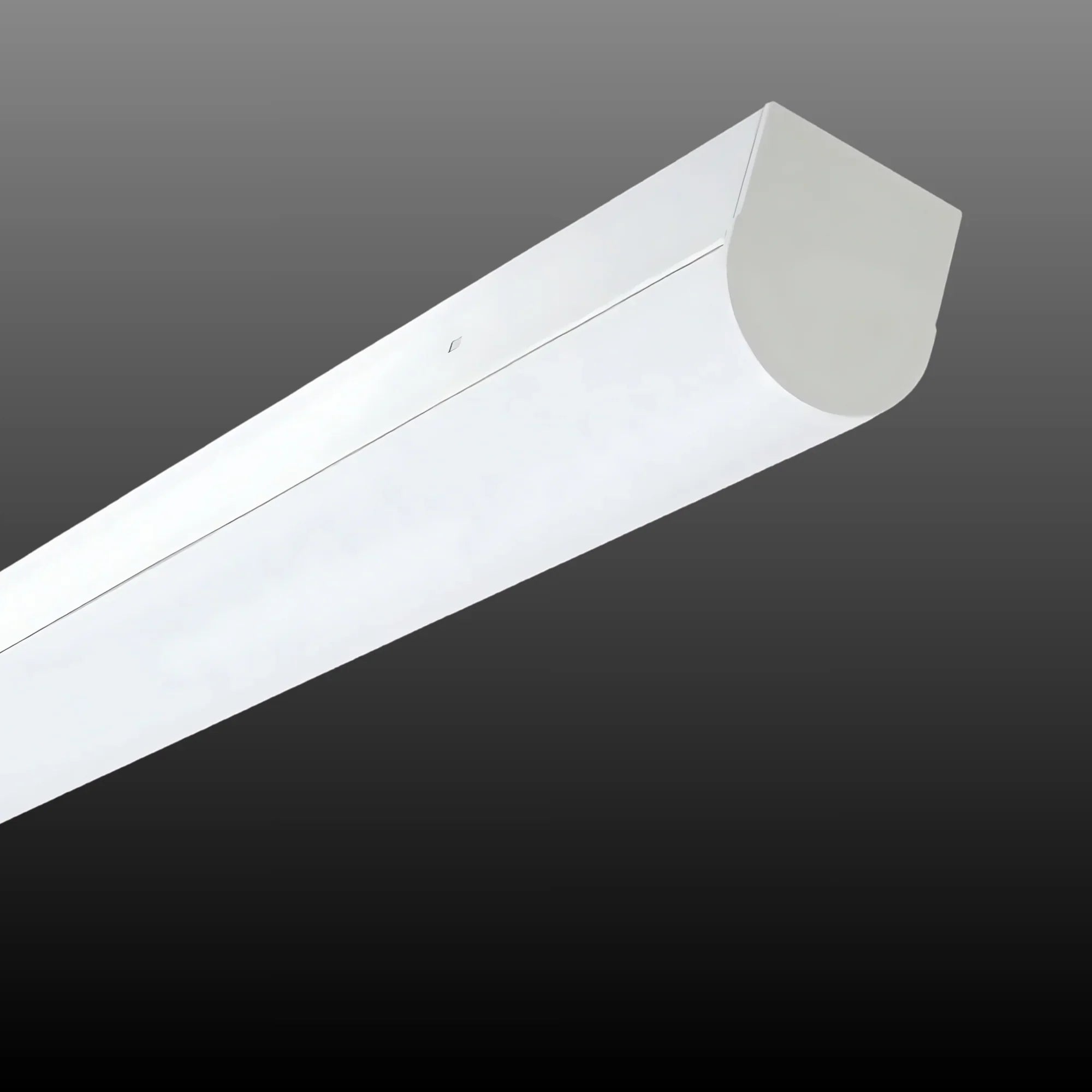

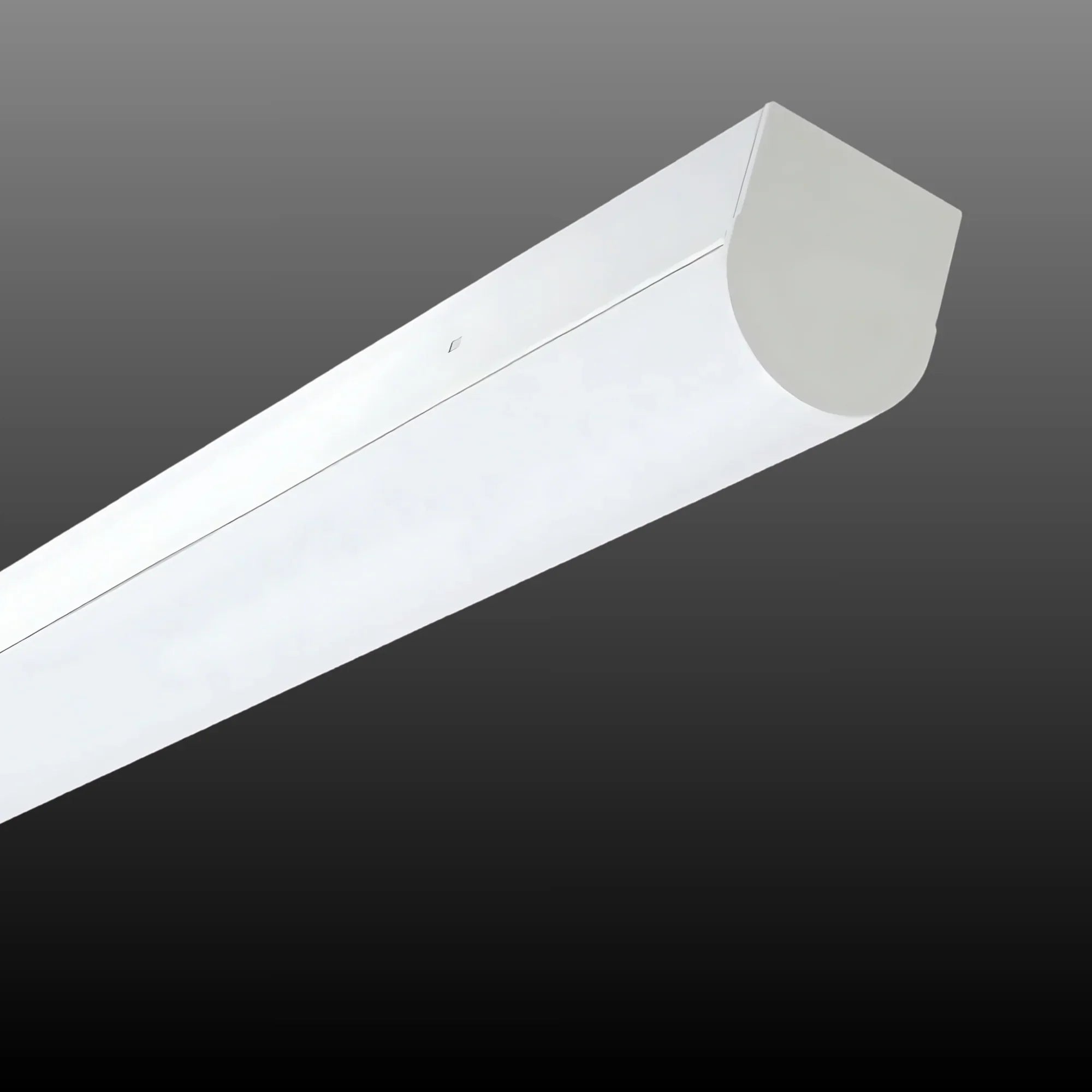

4ft LED Strip Light Fixture, 36W, 5200 Lumens, 35K/40K/50K, 120-277V

Choose your option

LED Wall Pack, 9000 Lumens, 60 Watts, 30K|40K|50K, On/Off Photocell, 120-277V

Choose your option

LED Wall Pack, 65 Watts, 8300 Lumens, 30K/40K/50K, 120-277V

Choose your option

4ft LED Strip Light Fixture, 4000 Lumens, 4000K, 120/277V

Choose your option

LED Linear High Bay, 130W, 19600 Lumens, 5000K, 120-277V

Choose your option

LED Cutoff Wall Pack, 15W, 1900 Lumens, 30K/40K/50K, 120-277V

Choose your option

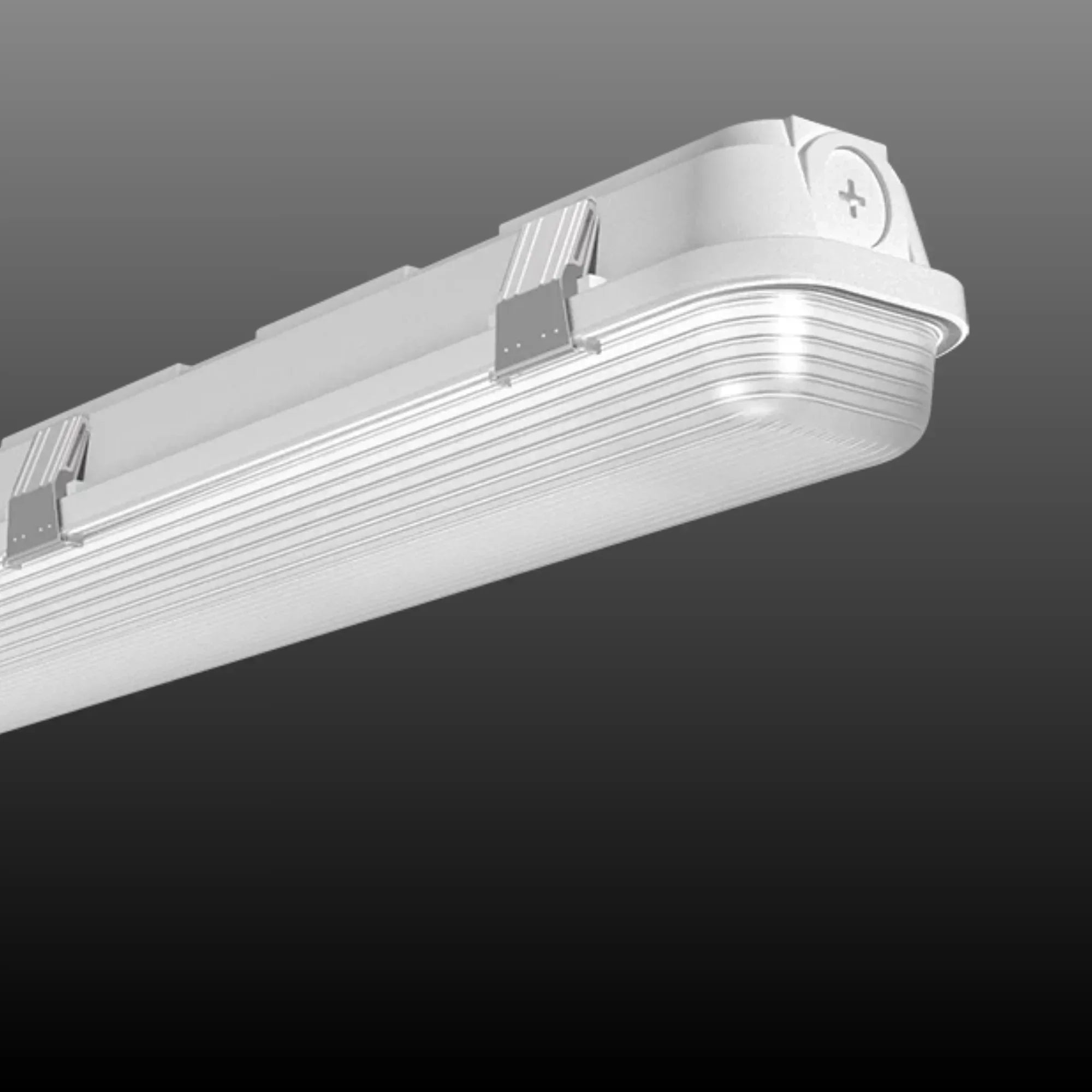

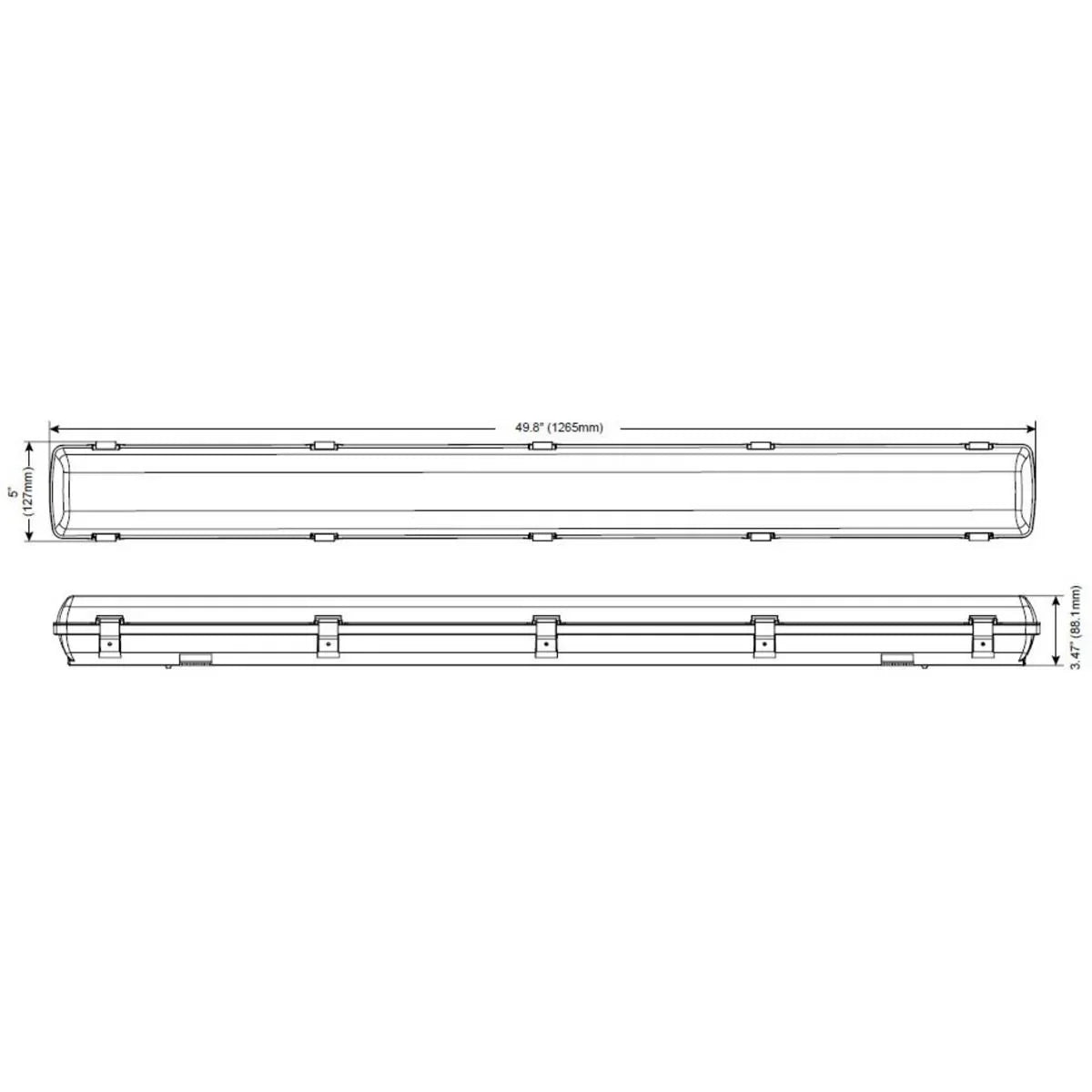

4ft Vapor Tight LED Light, 50W, 6800 Lumens, 35K/40K/50K, 120-277V

Choose your option

LED Cutoff Wall Pack, 40W, 5400 Lumens, 30K/40K/50K, 120-277V

Choose your option

4ft LED Strip Light Fixture, 5000 Lumens, 4000K, 120-277V

Choose your option

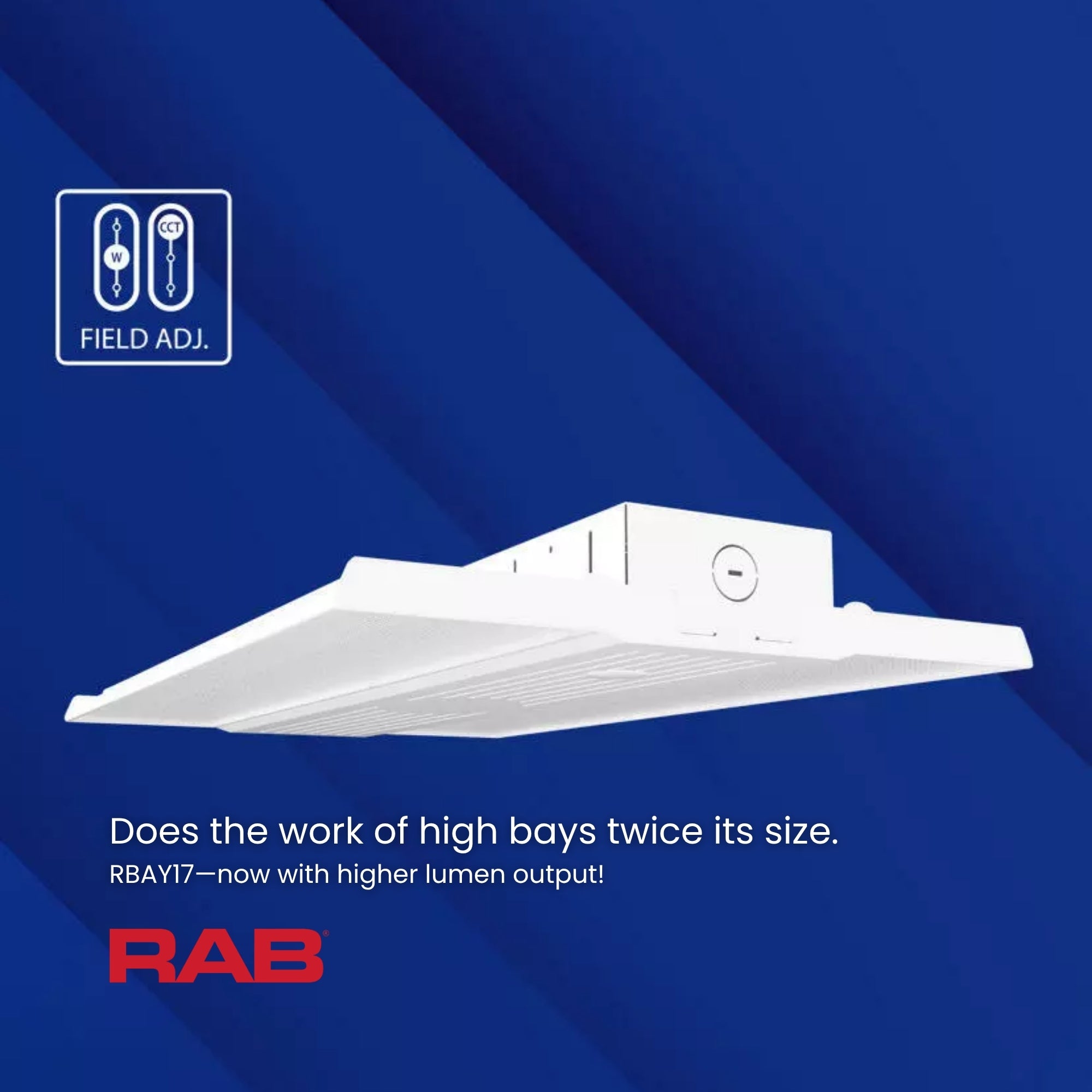

Linear High Bay LED Light, 160W, 24000lm, 4000K/5000K, 120-347V

Choose your option

UFO High Bay Fixture, 240W, 36000 Lumens, 35K/40K/50K, 120-277V, Black

Choose your option

LED Cutoff Wall Pack, 13W, 1720 Lm, 30K/40K/50K, 120-277V, Bronze

Choose your option

LED Cutoff Wall Pack, 30W, 3800 Lumens, 30K/40K/50K, 120-277V

Choose your option

High Bay LED Light, 20350lm, 130W, 35K/40K/50K, 120/277V

Choose your option

LED Wall Pack, 8100 Lumens, 60 Watts, 30K/40K/50K, On/Off Photocell, 120-277V

Choose your option

4ft LED Shop Light High Bay Fixture, 6 Lamp Holder, Ballast-Free (Bulbs Not Included)

Choose your option

High Bay UFO LED Light, 22000 Lumens, 150W, 30K/40K/50K, 120/277V, White

Choose your option

LED Mini Wall Pack With Photocell, 20W, 3000 Lumens, 30K/40K/50K, 120-277V, Bronze

Choose your option

4ft LED Strip Light Fixture, 40W, 6000 Lumens, 35K/40K/50K, 120-277V

Choose your option

UFO High Bay Light, 240W, 36000 Lumens, 4000K/5000K, 120-277V, Black

Choose your option

LED Wall Pack, 15700 Lumens, 100W, 30K|40K|50K, On/Off Photocell, 120-277V

Choose your option

LED Mini Wall Pack With Photocell, 16W, 1600 Lumens, 30K/35K/40K/50K/65K, 120V

Choose your option

Sylvania 62240 LED Wall Pack Light - 7000 Lumens, 50W, 5000K Daylight, 175W MH Replacement

Choose your option

8ft LED Strip Light Fixture, 8000 Lumens, 4000K, 120/277V

Choose your option

UFO LED High Bay Light, 90W, 13100 Lumens, 5000K, 120/277V

Choose your option

2ft High Bay LED Light, 22000 Lumens, 165W, 4000K|5000K, 120/277V

Choose your option

UFO High Bay Fixture, 150W, 22500 Lumens, 35K/40K/50K, 120-277V, White

Choose your option

LED Wall Pack, 9000 Lumens, 60W, 30K/40K/50K, 120/277V, Adjustable Throw

Choose your option

4ft Vapor Tight LED Light, 35W, 4590 Lumens, 5000K, 120-277V

Choose your option

Optimizing Your Facility with The Right Warehouse Lighting

Efficient warehouse lighting provides numerous benefits. Firstly, it enhances visibility, allowing employees to locate items quickly and accurately. This reduces the time spent on searching for products, resulting in improved efficiency and order fulfillment. Secondly, proper lighting promotes the safety of warehouse workers, reducing the risk of accidents and injuries. Well-lit areas minimize the chances of falls, collisions, and merchandise damage. Lastly, efficient lighting contributes to a more comfortable working environment, reducing eye strain and fatigue. This leads to happier employees and increased productivity.

Industrial Warehouse Lighting Solutions

Industrial warehouses have unique lighting requirements due to their size and nature of operations. These large-scale facilities require lighting solutions that can deliver high visibility, energy efficiency, and durability. Linear high bay lights are a versatile lighting solution for industrial warehouses. They provide even illumination and can be easily installed in various configurations. Linear high bay lights are commonly used in assembly lines, storage areas, or large workspaces.

LED high bay lights are the most popular lighting option for industrial warehouses. They offer high lumen output, ensuring bright illumination across large areas. LED high bay lights are energy-efficient, long-lasting, and require minimal maintenance.

Consider these industrial warehouse lighting solutions to enhance visibility, improve safety, and optimize energy usage in your facility.

Energy-Saving Options for Warehouse Lighting

Energy-saving options for warehouse lighting are not only environmentally friendly but also contribute to significant cost savings. Here are some energy-saving options to consider for your warehouse lighting:

- LED Lighting: LED lighting is the most energy-efficient option available for warehouse lighting. LEDs consume significantly less electricity than traditional lighting solutions, resulting in reduced energy bills. Additionally, LEDs have a longer lifespan, reducing the frequency of replacements and maintenance.

- Daylight Harvesting: Daylight harvesting utilizes natural light to supplement artificial lighting in warehouses. By utilizing sensors and controls, the system adjusts the artificial lighting levels based on the amount of natural light available. This ensures that lights are only at full brightness when necessary, saving energy during daylight hours.

- Occupancy Sensors: Occupancy sensors are an effective way to save energy in warehouses. These sensors detect motion and automatically turn lights on or off based on occupancy. By only illuminating areas when they are in use, occupancy sensors can significantly reduce energy consumption.

- Dimming and Zoning: Dimming and zoning allow for adjusting the brightness levels of lights in specific areas of the warehouse. By reducing the intensity of lighting in areas with lower activity or during non-operational hours, energy consumption can be minimized. This can be achieved through the use of dimming controls and partitioning the warehouse into zones for independent lighting control.

Implementing these energy-saving options can result in substantial cost savings and environmental benefits for your warehouse.

Benefits of LED Warehouse Lighting

LED warehouse lighting offers several advantages over traditional lighting solutions. Firstly, LEDs are highly energy-efficient, consuming significantly less electricity than traditional fluorescent or incandescent lights. This translates to substantial cost savings on energy bills, making LED warehouse lighting a cost-effective option in the long run. Additionally, LEDs have a longer lifespan, reducing the frequency of replacements and maintenance, further reducing costs.

LEDs also provide superior lighting quality. They produce bright and uniform illumination, ensuring consistent visibility throughout the entire warehouse. This helps employees perform their tasks more accurately and efficiently. Furthermore, LEDs have instant startup capabilities, eliminating the need for warm-up time. This means that the lights can be turned on and off without delay, providing convenience and flexibility.

LEDs also provide superior lighting quality. They produce bright and uniform illumination, ensuring consistent visibility throughout the entire warehouse. This helps employees perform their tasks more accurately and efficiently. Furthermore, LEDs have instant startup capabilities, eliminating the need for warm-up time. This means that the lights can be turned on and off without delay, providing convenience and flexibility.

Choosing the Right High Bay LED Lights for Your Warehouse

Selecting the right high bay LED lights for your warehouse is crucial for achieving optimal lighting conditions. Here are some factors to consider when choosing high bay LED lights:

- Lumen Output: The lumen output determines the brightness of high bay LED lights. Consider the size of your warehouse and the level of illumination required for different areas. Higher lumen output is suitable for larger spaces or areas that require high visibility, while lower lumen output may be sufficient for smaller spaces or areas with lower lighting needs.

- Color Temperature: Color temperature affects the appearance of light, ranging from warm to cool tones. Consider the activities performed in your warehouse and choose a color temperature that suits the specific tasks. For example, a cooler color temperature (5000K-6500K) is ideal for areas that require high visibility, while a warmer color temperature (3000K-4000K) may be more suitable for storage areas or break rooms.

- Beam Angle: The beam angle determines the spread of light from high bay LED lights. Consider the height and layout of your warehouse to determine the appropriate beam angle. A narrower beam angle is suitable for taller ceilings, while a wider beam angle is ideal for lower ceilings.

- Energy Efficiency: Opt for high bay LED lights that are energy-efficient to reduce electricity consumption and lower utility costs. Look for lights that are ENERGY STAR certified or have high efficacy ratings. LED technology offers the highest energy efficiency compared to other lighting options.

- Durability and Lifespan: Consider the durability and lifespan of high bay LED lights. Look for lights that are made with high-quality materials and have a long lifespan. This will reduce the frequency of replacements and maintenance, resulting in cost savings over time.

By considering these factors and selecting high bay LED lights that meet your warehouse's specific requirements, you can ensure optimal lighting performance.

Cost-Saving Strategies with Warehouse Lighting

Implementing cost-saving strategies with warehouse lighting can significantly reduce operational expenses. Here are some strategies to consider:

- LED Lighting Retrofit: Retrofitting existing lighting fixtures with LED technology is a cost-effective way to improve energy efficiency. High bay retrofit bulbs can be installed in existing fixtures, eliminating the need for complete replacements. This allows businesses to benefit from energy savings without incurring high upfront costs.

- Energy Audits: Conducting energy audits can help identify areas of inefficiency and opportunities for improvement. Professional energy auditors can assess your warehouse's lighting system and provide recommendations for energy-saving measures. By implementing their suggestions, you can optimize energy usage and reduce costs.

- Lighting Controls: Implementing lighting controls, such as dimmers or occupancy sensors, can help optimize energy usage. Dimmers allow you to adjust the brightness of lights according to specific needs, reducing energy consumption during non-operational hours. Occupancy sensors ensure that lights are only in use when needed, minimizing unnecessary energy waste.

- Maintenance and Cleaning: Regular maintenance and cleaning of lighting fixtures can improve their performance and lifespan. Dust and dirt can accumulate on fixtures, reducing their efficiency. By keeping fixtures clean and replacing any faulty components, you can ensure optimal lighting conditions and reduce the need for premature replacements.

- Utilize Natural Light: Make the most of natural light by utilizing daylight harvesting techniques and skylights. By incorporating natural light into your warehouse, you can reduce the need for artificial lighting during daylight hours, resulting in energy savings.

By implementing these cost-saving strategies, you can optimize your warehouse lighting system and reduce operational expenses.

The Role of Motion Sensors in Warehouse Lighting

Motion sensors play a significant role in warehouse lighting by providing energy-saving and convenience features. These sensors detect movement and automatically turn lights on or off based on occupancy. Here are some benefits of using motion sensors in warehouse lighting:

- Energy Efficiency: Motion sensors help minimize energy wastage by ensuring that lights are only in use when needed. When there is no activity detected, the lights automatically turn off, reducing unnecessary energy consumption. This can lead to substantial cost savings on energy bills.

- Convenience: Motion sensors provide convenience by eliminating the need for manual light controls. In a warehouse setting, where employees are constantly moving between different areas, having lights automatically turn on and off simplifies their tasks. This also eliminates the risk of lights being accidentally left on, further reducing energy waste.

- Safety: Motion sensors contribute to the safety of warehouse operations. By automatically turning on lights when someone enters an area, they ensure that employees have clear visibility, reducing the risk of accidents and injuries. In emergency situations or power outages, motion sensors can also activate emergency lighting, helping to maintain a safe working environment.

- Extended Lifespan: Using motion sensors to control lighting can extend the lifespan of light fixtures. Since lights are only in use when needed, they experience less wear and tear, resulting in reduced maintenance and replacement costs.

By incorporating motion sensors into your warehouse lighting system, you can enhance energy efficiency, convenience, and safety.

Boost Productivity with Bees Lighting

Efficient warehouse lighting is essential for optimizing operations and reducing costs. LED warehouse lighting offers numerous benefits, including energy efficiency, long lifespan, and improved visibility. Choosing the right lighting fixtures, such as high bay lights, and considering factors like motion sensors, can further enhance efficiency and safety. Implementing energy-saving strategies and proper installation and maintenance practices can lead to substantial cost savings. By investing in efficient warehouse lighting, businesses can boost productivity, create a safer working environment, and achieve long-term cost savings.

Bees Lighting carries large inventory and wide selection from industry leading manufacturers of LED high bays to exceed the demands of the most challenging industrial and warehouse facility spaces. Switch now and get all the benefits of energy-saving LED technology like occupancy sensors and motion sensors, minimal hot spots, and compatible lighting controls. LED warehouse lighting is the next step in large-scale lighting for industrial and commercial businesses. Get all your warehouse lighting needs only at Bees Lighting. Upgrading your lighting from HID and fluorescent to LED keeps your warehouse at top-notch performance and maximizes your investment.